There’s a lot of hype about how much extra resources are needed to build electric cars. How much of it’s true and how long does it take to repay that build debt. We’ll look at a couple of the myths and find some answers.

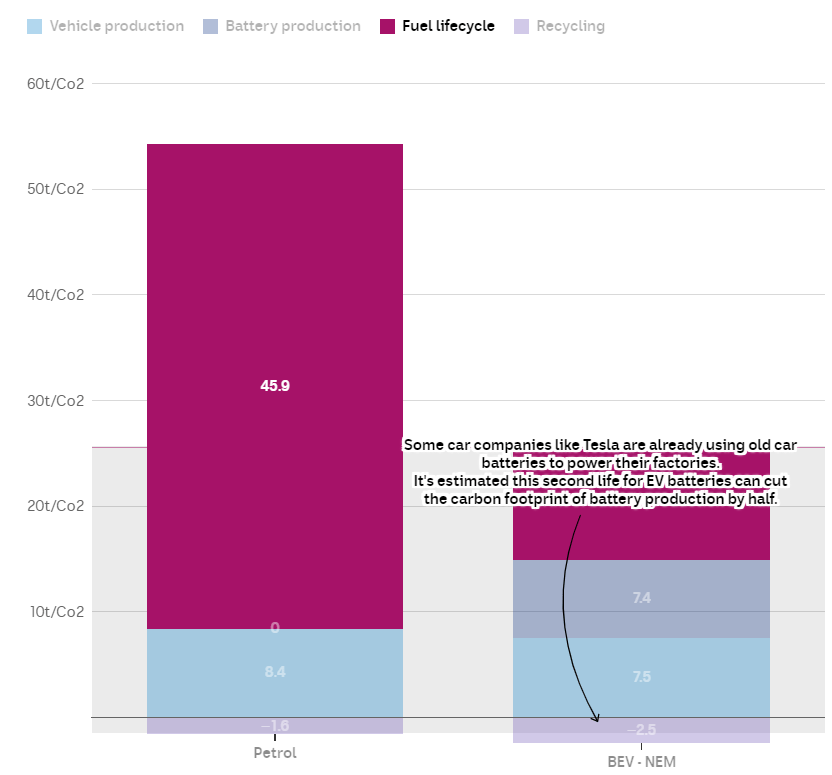

Myth #1 – Even after years of burning petrol, electric cars battery construction still produces more CO2.

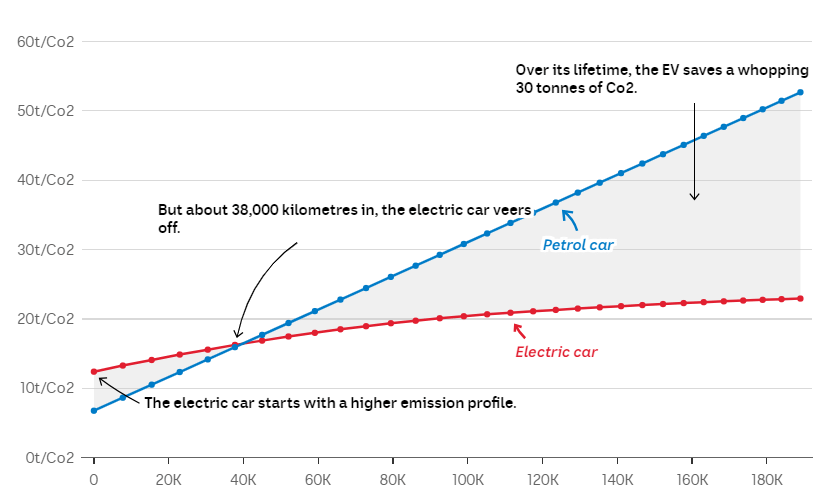

When we look at car construction, the shell of the car isn’t that much different Four wheels, the chassis, the body and interior are largely the same. The difference is instead of an internal combustion engine and fuel tank, we need an electric motor, or maybe a couple of motors, and a battery.

It’s true, the construction of the battery takes up quite a lot of resources and contruction creates more CO2 than building an internal combusion engine.

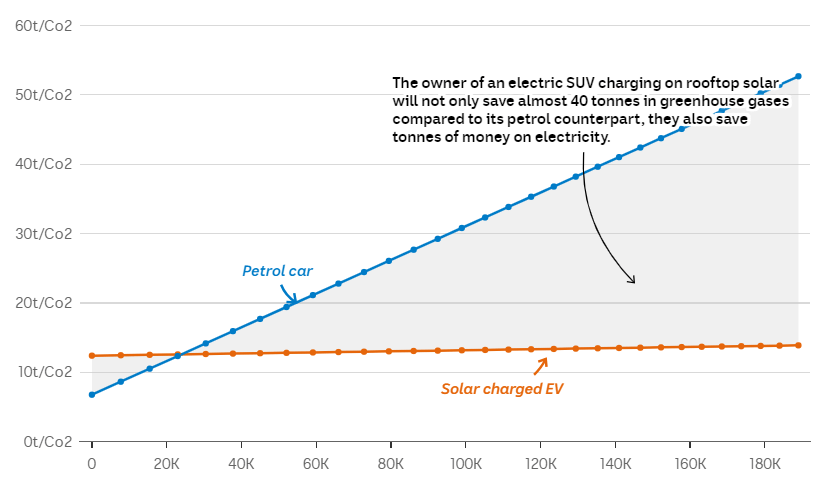

Electric cars don’t produce much CO2, but there can be some created when making electricity, depending on how that electricity is created. In Tasmania for instance, the electricity is extremely green, primarily from hydro power. In the rest of the country, power generation includes some fossil fuels, usually coal. Regardless of how the electricity is produced, grid electricty for electric cars produces less CO2 than driving an equivalent sized ICEV.

Research published by the ABC backs this up.

It’s true, the construction of the battery takes up quite a lot of resources and contruction creates more CO2 than building an internal combusion engine.

Electric cars don’t produce much CO2, but there can be some created when making electricity, depending on how that electricity is created. In Tasmania for instance, the electricity is extremely green, primarily from hydro power. In the rest of the country, power generation includes some fossil fuels, usually coal. Regardless of how the electricity is produced, grid electricty for electric cars produces less CO2 than driving an equivalent sized ICEV.

Research published by the ABC backs this up.

Myth #2 – battery construction uses a lot of water

The production of EV batteries does require significant amounts of water, which has led to concerns about water usage. However, it’s important to note that fossil fuel extraction and refining also require substantial amounts of water.

While the water usage in lithium mining, a key component of EV batteries, is a valid concern, it’s also a challenge that the industry is actively working to address. Innovations in water recycling and more efficient extraction methods are being developed to reduce the water footprint of EV battery production.

Batteries come in various sizes and shapes. They are manufactured by different companies using different techniques. The best case for battery contrction is that it uses about 3,000 litres. The worst case is 4 times that at 12,000 litres. It’s a lot of water, yes, but let’s compare that with how much water is needed to produce petrol.

It takes between 2.8 and 6.6 litres of water to produce a litre of petrol. Let’s use the lower end of that and say it’s 3 (for easy maths). Then take the upper limit for a battery of 12,000 litres. That same 12,000 litres of water used to produce a battery could produce 4,000 litres of petrol. If a petrol tank is 50 litres, That’s only 80 tanks of fuel. So in less than 2 years of driving (1 tank per week) a fairly average driver consume 12,000 litres of water to produce the fuel used. So an EV battery is water neutral in under 2 years (using the most conservative case of minimal water for petrol and maximum water for a battery).

We haven’t considered the water involved in making the internal combustion engine itself.

Source: Water for Petrol Production

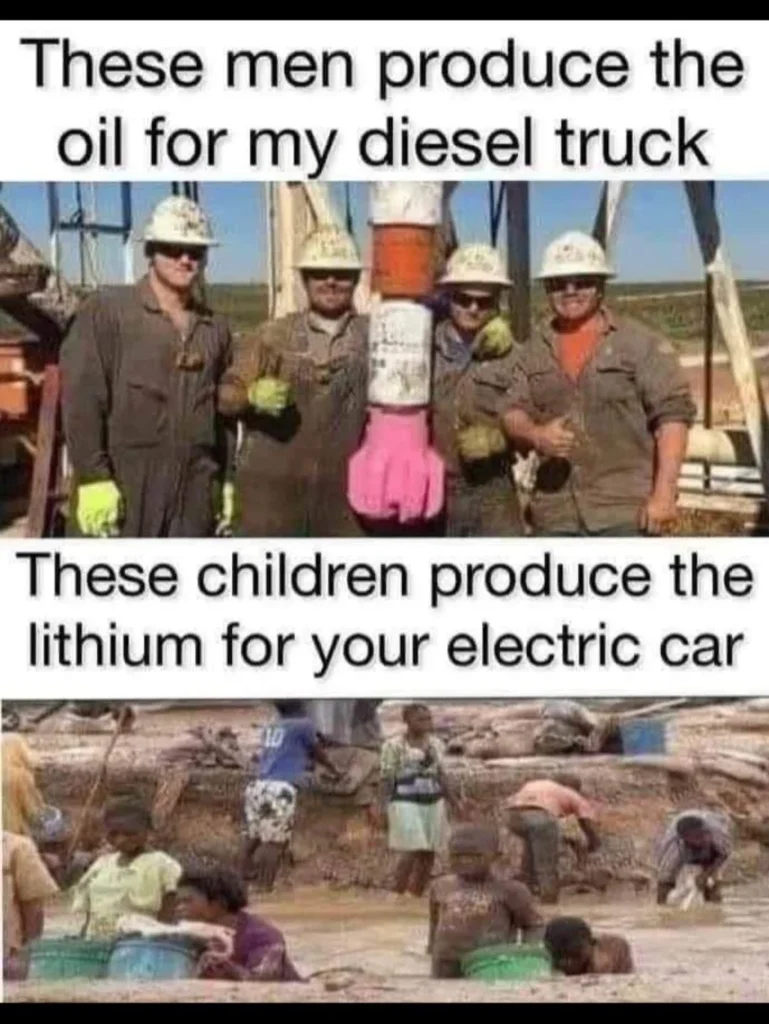

Myth #3 Lithium for electric cars is mined by children

Companies try to source their lithium ethically as most companies do with any commodities mined or extracted today. Lithium mining is no more exploitative of children than any other industry including oil.

According to the British Geological Survey, there are two main sources of lithium. Salt Lakes in South America, and from mining in Australia, Canada, China and Zimbabwe. A secondary source is dried lake beds and clay pans in the USA. Six of the largest mines are in Australia, which has very strict child labour laws.

According to thee World Economic Forum: Australian production exceeds 55,000 tonnes per annum, more than twice the second biggest producer Chile at 26,000 tonnes. Chile uses salt lake extraction, which is reliant on machinery, and unlikely to use children. Australia produces just over half the world’s lithium and Chile 25%. So chances are the lithium in your batteries is ethically produced in Australia or Chile.

According to the British Geological Survey, there are two main sources of lithium. Salt Lakes in South America, and from mining in Australia, Canada, China and Zimbabwe. A secondary source is dried lake beds and clay pans in the USA. Six of the largest mines are in Australia, which has very strict child labour laws.

According to thee World Economic Forum: Australian production exceeds 55,000 tonnes per annum, more than twice the second biggest producer Chile at 26,000 tonnes. Chile uses salt lake extraction, which is reliant on machinery, and unlikely to use children. Australia produces just over half the world’s lithium and Chile 25%. So chances are the lithium in your batteries is ethically produced in Australia or Chile.

Sources:

British Geological Survey

British Geological Survey

Myth#4 Batteries from electric cars will pile up and go to landfill.

Recycling a petrol car removes aound 1.6 tonnes of CO2 from the atmosphere. Recycling an EV currently removes 2.5 tonnes.

Recycling cars is actually 56% better at removing CO2 from the environment.

Reusing the used EV battery as a household solar battery or in large scale battery packs for grids and factories could improve the environmental impact even further. Re-use of a resource without significant processing is always better than recycling by re-processing. Not having to make household batteries by re-using old EV batteries certainly makes environmental sense.

Recycling cars is actually 56% better at removing CO2 from the environment.

Reusing the used EV battery as a household solar battery or in large scale battery packs for grids and factories could improve the environmental impact even further. Re-use of a resource without significant processing is always better than recycling by re-processing. Not having to make household batteries by re-using old EV batteries certainly makes environmental sense.